Homogenization in the Cannabis Industry

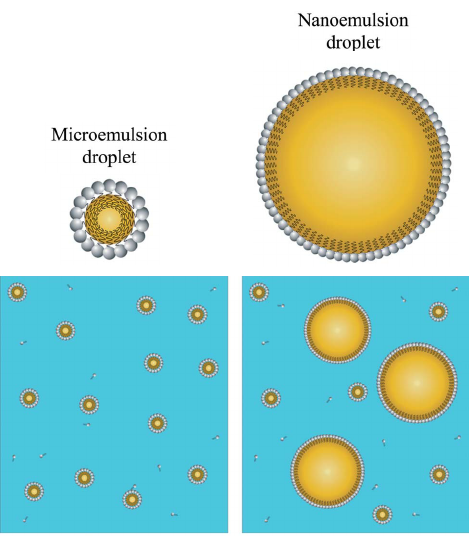

Our High Pressure technology uses mechanical forces to reduce the size of particles in a liquid. The ideal outcome is the efficient creation of smaller particles sizes with a more uniform, tight distribution in the processed liquid (Nanoemulsion / Dispersion).

Benefits of our Technology

![]() Increased bioavailability (up to 75%) of active ingredients in your Cannabis products.

Increased bioavailability (up to 75%) of active ingredients in your Cannabis products.

![]() Smaller particles are easier to mix into your products and stay mixed (with the aid of an emulsifier - we can advise).

Smaller particles are easier to mix into your products and stay mixed (with the aid of an emulsifier - we can advise).

![]() Cannabinoid nanoemulsions stay in solution evenly so can help improve product consistency and shelf life.

Cannabinoid nanoemulsions stay in solution evenly so can help improve product consistency and shelf life.

![]() Nano Cannabinoids, such as emulsions, are water-compatible so can be added wide range of products including beverages.

Nano Cannabinoids, such as emulsions, are water-compatible so can be added wide range of products including beverages.

![]() In most cases less surfactants are required during processing. The use of all-natural surfactants may also possible.

In most cases less surfactants are required during processing. The use of all-natural surfactants may also possible.

Our versatile Cannabis Homogenizers - features

![]() Ultra high pressures to 60,000 psi (4200 bar) and processing from 3ml, e.g. for Lab samples, up to flow rates in excess of 1000 l/hour (264 USG) for full production systems.

Ultra high pressures to 60,000 psi (4200 bar) and processing from 3ml, e.g. for Lab samples, up to flow rates in excess of 1000 l/hour (264 USG) for full production systems.

![]() Scalable and reproducible results to improve further your product consistency.

Scalable and reproducible results to improve further your product consistency.

![]() Easy to use and maintain with low maintenance costs. We offer full global support

Easy to use and maintain with low maintenance costs. We offer full global support

![]() Versatile and reliable with adjustable process pressures and temperature control.

Versatile and reliable with adjustable process pressures and temperature control.

Contact us here to discuss your requirements.

Laboratory scale

Improved processing efficiency For R&D and small scale production.

Flow rates from 1ml to 275ml per minute / 16 L per hour and a wide range of sample sizes.

Easy to use and highly versatile.

Pilot Systems

Unrivalled performance and versatility for process R&D, process refinement and small scale production.

Up to 130 l/hr of continuous, smooth delivery and options of piston gap and micro-channel processing technology.

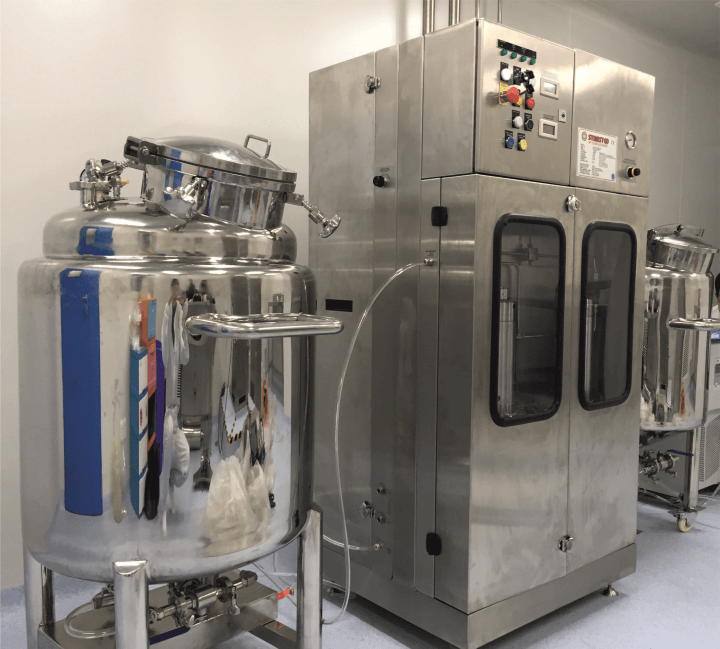

Production Systems

Fully featured Production systems, for the most demanding requirements, with flow rates up to 1000 l/hr (264 USG/hr).

Simple operation, easy to clean and service with global support. PLC based control logic now with touch screen HMI interface.

Mulitple Temperature control options enabling pre-cooling, pre-heating and post-cooling.

Contact us here to discuss your requirements.